Product Name:

Product Name:R5 KB 0020–0040 DF Oil-Lubricated Rotary Vane Vacuum Pump

R5 KB rotary vane vacuum pumps are characterized by their compact construction, light weight and high performance.

They are perfectly suited for installation in confined spaces, for example in vacuum packaging machines. The integrated motor and transmission make them the ideal choice for fixed installations.

R5 KB feature highly durable Busch fiber-reinforced epoxy resin vanes as standard. This ensures an optimum performance and long service life.

Advantages

1.Compact structure: integrated motor and transmission, which reduces height and weight, suited for fixed installation in confined spaces such as vacuum packaging machines;

2.Reliable: Robust and durable structure, highly durable blade, proven rotary vane technology, long service life;

3.Flexible: A variety of options are available, which can be easily adjusted according to the requirements and processes of each customer.

Accessories

· Gas-ballast valve

· Various inlet filters

· Filter pressure gauge

· Oil level switch

· Vacuum pump oils for all applications

· Vacuum regulating unit

Main Parameters

| TECHNICAL DATA | R5 KB 0020 D | R5 KB 0025 F | R5 KB 0040 D |

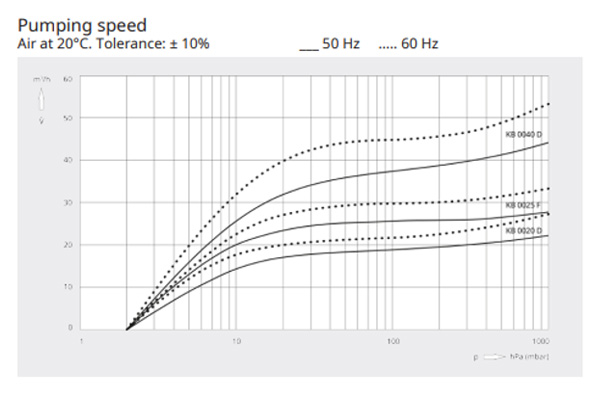

| Nominal pumping speed | 14.1 ACFM | 17.7 ACFM | 28.2 ACFM |

| Ultimate pressure | 1.5 TORR | 1.5 TORR | 1.5 TORR |

| Nominal motor rating | 1.0 HP | 1.5 HP | 2.0 HP |

| Nominal motor speed | 3600 RPM | 3600 RPM | 3600 RPM |

| Noise level (ISO 2151) | 70 dB(A) | 73 dB(A) | 75 dB(A) |

| Oil capacity | 0.5 qts. | 0.5 qts. | 0.8 qts. |

| Weight approx. | 41.8 Lbs. | 44 Lbs. | 63.8 Lbs. |

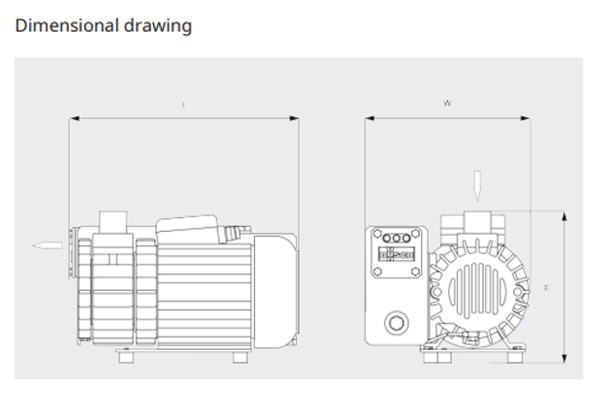

| Dimensions (L x W x H) | 12.7 x 9.1 x 8.3 inches | 13.7 x 9.8 x 9 inches | 17 x 10.1 x 9.4 inches |

| Gas outlet | – | – | G 1¼" |

| Gas inlet | G ¾" | G ¾" | G 1¼" |

Market & Applications

Food processing

Meat fillers

Powder processing

Meat marinators

Packaging

Money packaging

Blister packaging

Clipping machines

Labeling

Cartoning machines

Tray loading systems

Chamber packaging machines table top

Plastics processing

SSP recycling

Vacuum bagging

Pneumatic conveying

Injection molding

Thermoforming

Resin transfer molding (RTM)

***The content above originates from website of ULVAC https://www.ulvac.co.jp/.***

0086-533-7987888

0086-533-7987888

export1@wjcreator.com

export1@wjcreator.com