Product Name:

Product Name:DOLPHIN LB 0063–0184 A Liquid Ring Vacuum Pump

DOLPHIN are the robust liquid ring vacuum pumps and compressors from Busch. This series encompasses decades of experience in the use and further development of liquid ring technology.

Their proven operating principle provides virtually isothermal (cold) compression which is especially useful for sensitive or hazardous gases.

They are the perfect solution for demanding applications. For example, the evacuation of saturated gases and vapors.

The DOLPHIN series comprises a large variety of sizes and assemblies: single- or two-stage, with a directly flange-mounted motor, or assembled on a base plate, vacuum pumps and compressors.

DOLPHIN LA/LB is our series of robust and reliable liquid ring vacuum pumps in base plate design. Their proven operating principle allows them to be used in many sectors of industry.

Even demanding applications, such as evacuating saturated gases and vapors are possible without problems. Different operating fluids may be used according to process conditions.

Thanks to the modular design, various assemblies are possible. The precisely dimensioned range of sizes, a wide variety of shaft sealing options, choice of accessories and construction materials allows you to find the perfect DOLPHIN LA/LB for your process.

DOLPHIN LA are single-stage vacuum pumps whereas DOLPHIN LB have two stages for a higher vacuum.

Advantages:

1.Robust: Proven technology, durable single-stage construction;

2.Reliable: Extremely high vapor and particle tolerance;

3.Flexible: Wide range of construction materials, including cast iron (EN-GJL-200), many grades of stainless steel and even titanium, ATEX-certified version available (Cat 1(i)/2(o) IIC T5), different operating fluids possible, operation as compressor possible.

Accessories

Partial or total recirculation systems

Liquid separator

Cavitation protection

Heat exchanger

Gas ejector

Wide selection of motors

Non-return valves

Vacuum relief valves

Main Parameters

(ISO 50Hz)

| TECHNICAL DATA | DOLPHIN LB 0063 A | DOLPHIN LB 0113 A | DOLPHIN LB 0144 A | DOLPHIN LB 0184 A |

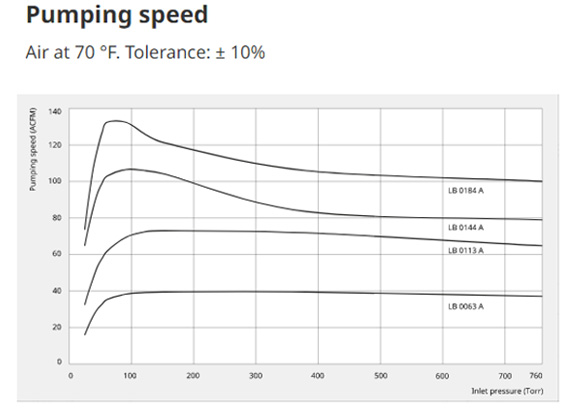

| Nominal pumping speed | 60 m³/h | 110 m³/h | 140 m³/h | 180 m³/h |

| Ultimate pressure | 33 hPa (mbar) | 33 hPa (mbar) | 33 hPa (mbar) | 33 hPa (mbar) |

| Max. overpressure | 2 bar(g) | 2 bar(g) | 2 bar(g) | 2 bar(g) |

| Nominal motor rating | 3 kW | 4 kW | 4 kW | 5.5 kW |

| Nominal motor speed | 1450 min⁻¹ | 1450 min⁻¹ | 1450 min⁻¹ | 1450 min⁻¹ |

| Noise level (ISO 2151) | 72 dB(A) | 72 dB(A) | 72 dB(A) | 72 dB(A) |

| Weight approx. | 77 kg | 78 kg | 103 kg | 119 kg |

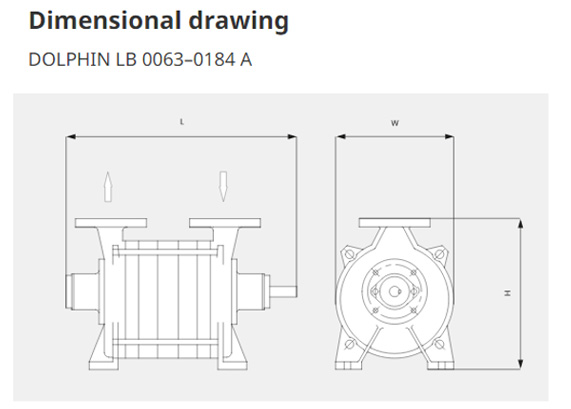

| Dimensions (L x W x H) | 489 x 250 x 320 mm | 529 x 250 x 320 mm | 596 x 270 x 405 mm | 656 x 270 x 405 mm |

| Gas inlet | DN 40 PN 10 | DN 40 PN 10 | DN 40 PN 10 | DN 40 PN 10 |

| Gas outlet | DN 40 PN 10 | DN 40 PN 10 | DN 40 PN 10 | DN 40 P |

(ISO 60Hz)

| TECHNICAL DATA | DOLPHIN LB 0063 A | DOLPHIN LB 0113 A | DOLPHIN LB 0144 A | DOLPHIN LB 0184 A |

| Nominal pumping speed | 65 m³/h | 120 m³/h | 180 m³/h | 225 m³/h |

| Ultimate pressure | 33 hPa (mbar) | 33 hPa (mbar) | 33 hPa (mbar) | 33 hPa (mbar) |

| Max. overpressure | 2 bar(g) | 2 bar(g) | 2 bar(g) | 2 bar(g) |

| Nominal motor rating | 4 kW | 4 kW | 5.5 kW | 7.5 kW |

| Nominal motor speed | 1750 min⁻¹ | 1750 min⁻¹ | 1750 min⁻¹ | 1750 min⁻¹ |

| Noise level (ISO 2151) | 72 dB(A) | 72 dB(A) | 72 dB(A) | 72 dB(A) |

| Weight approx. | 77 kg | 78 kg | 103 kg | 119 kg |

| Dimensions (L x W x H) | 664 x 250 x 320 mm | 704 x 250 x 320 mm | 762 x 270 x 405 mm | 822 x 270 x 405 mm |

| Gas inlet | DN 40 PN 10 | DN 40 PN 10 | DN 40 PN 10 | DN 40 PN 10 |

| Gas outlet | DN 40 PN 10 | DN 40 PN 10 | DN 40 PN 10 | DN 40 |

Market & Applications

Chemical and pharmaceutical industries

Filtration

Evaporation

Distillation

Drying

Solvent recovery

Pneumatic conveying

Food processing

Pasteurizing

Sterilizing

Freeze drying

Powder processing

Vacuum cooling

Meat marinators

Meat tumblers

Meat cutters

Beverage filling

Pneumatic conveying of wet food waste

Oil and gas industry

Crude oil distillation

Triethylene glycol (TEG) regeneration

Monoethylene glycol (MEG) regeneration

Mud drying

Water pump priming

Seawater deaeration

Crude oil fractional distillation

Water degassing

Seawater deoxygenation

Vent gas recovery

Mud transfer

Petroleum refining

Packaging

Liquid packaging

Plastics processing

Extruder profile

Extruder compounding

Vacuum calibration

Extruder sheet/film

Vapor recovery

Railcar and truck loading

Storage tank venting

Storage tank filling

Vapor balancing

Volatile organic compounds (VOC) recovery

Woodworking

Impregnation

Drying

***The content above originates from website of ULVAC https://www.ulvac.co.jp/.***

0086-533-7987888

0086-533-7987888

export1@wjcreator.com

export1@wjcreator.com