0086-533-7987888

0086-533-7987888

export1@wjcreator.com

export1@wjcreator.com

|

In the chemical industry, vacuum equipment is as indispensable as water, electricity and compressed air. Vacuum is usually used to remove air or water vapor to prevent interference with the process. Vacuum can also improve the efficiency of the reaction process and the recovery rate of important compounds. In the vacuum state, the boiling point of the liquid decreases, which is very beneficial for processing thermosensitive materials. In the vacuum condition, the solid terminal products generated from the liquid are more uniform, and there are almost no holes caused by bubbles. In addition, it is safer to handle and transfer aggressive compounds under vacuum.

Due to the harsh working conditions and long working cycle of the chemical process, the vacuum pump must be reliable, durable and stable, and must also have the following properties:

❶ Capable of handling vapours from various solvents without damaging the pump

❷ It will not pollute the process and environment

❸ Waste generated shall be minimized

❹ The vacuum pump shall be corrosion resistant

❺ Capable of handling flammable gas or steam

Roots blower / Roots vacuum pumps (Leybold)

Multi-stage rotary lobe vacuum pump (Busch)

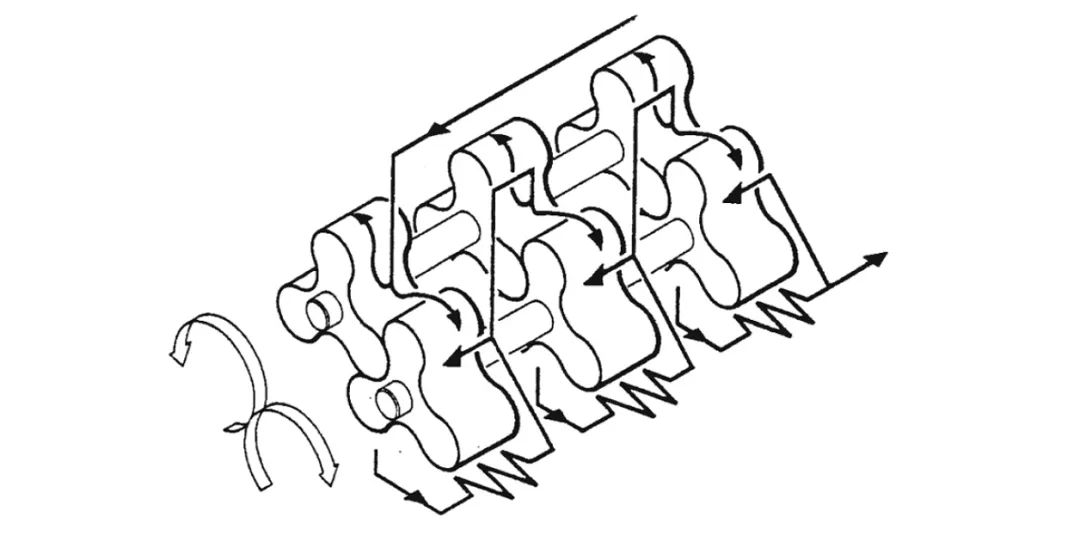

Roots vacuum pump is a large dry vacuum pump, which is widely used in the chemical industry. The pump is composed of three-stage three blade roots rotors in series, which are installed on the same shaft. The rotors at all levels are separated by the middle diaphragm to form pump cavities at all levels. The upper stage exhaust port is connected to the lower stage air inlet, and all levels are connected in series for air extraction. The diameter and shape of rotors at all levels are the same, and the width of rotors at all levels narrows towards the high-pressure side. However, this design requires interstage cooling, that is, the gas discharged from the upper stage is cooled through the heat exchanger before entering the inlet of the lower stage, as shown in the figure below. Although the three blade Roots dry pump can reduce the gas backflow, the pumped gas can only be discharged out of the pump after a tortuous journey, which is easy to cause the process materials to accumulate in the pump cavity, and the particulate impurities are not easy to be directly discharged out of the pump. Roots dry pump can pump 10Pa from the atmosphere at a speed of (36~360) L/s.

Claw dry vacuum pumps

Oil-free dry claw pumps (Leybold)

Dry claw vacuum pumps (Busch)

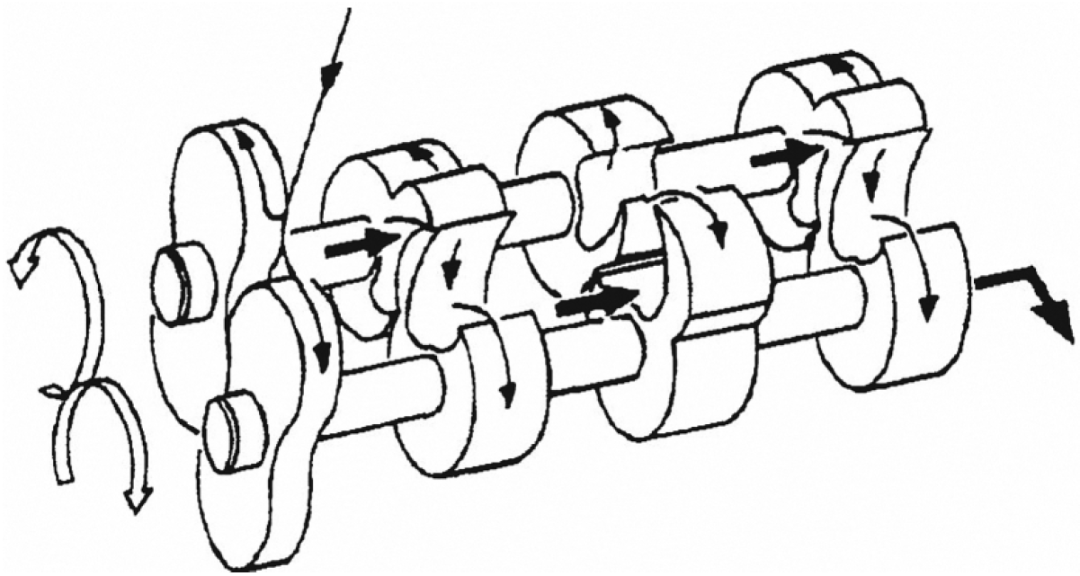

The rotor of claw type dry vacuum pump is characterized by high compression ratio under high pressure. The claw rotor also has two functions: one is used to intercept, transport and compress gas, and the other is to open and close the suction and exhaust ports at an appropriate time like a valve.

The limit pressure of claw type dry vacuum pump developed by Shandong Yining Environmental Protection Technology Co., Ltd. is ≤ 1Pa, and the pumping speed is (4~1600) L/s. Our company has developed a claw type dry vacuum pump made of graphite composite materials, which can be applied to the working conditions of strong corrosive media in the chemical industry, such as perchloric acid, hydroiodic acid, sulfuric acid, hydrofluoric acid, hydrobromic acid, hydrochloric acid, nitric acid, etc. At present, the vacuum pump has been used in the chemical industry in evaporation, distillation, drying, concentration and other working conditions.

Screw vacuum pump

Dry screw vacuum pump (Leybold / Busch)

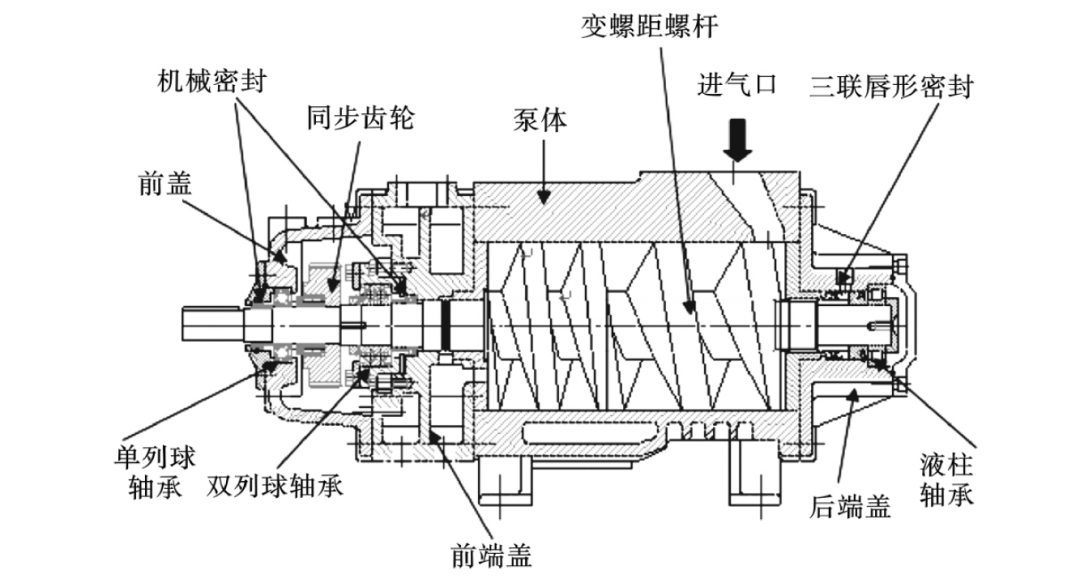

Screw vacuum pump has a series of advantages, such as wide pumping range, simple and compact structure, no friction components in the pump cavity, low energy consumption, no waste liquid discharge and low operating cost. Therefore, it is widely used in semiconductor, photovoltaic industry, chemical industry, pharmacy, petrochemical, space simulation, low pressure wind tunnel and other fields. Working principle of screw vacuum pump: a pair of synchronous gears drive the counter rotating screw. There is a certain gap between the screw and the screw, and between the screw and the pump chamber. There is no metal to metal contact. Thus, during the rotation of the screw, the extracted gas is sucked in from the air inlet and discharged to the exhaust port, as shown in the figure below.

Although claw type dry vacuum pump and screw vacuum pump are expensive, they have excellent performance, low operating cost, no waste liquid discharge problem, and are both energy-saving and environment-friendly. Therefore, the above two vacuum pumps are most suitable for chemical process applications.

Address: New Materials Pilot Zone of Science Town, Zibo city, Shandong Province, China

Tel 1: 0086-533-7987888

Email: export1@wjcreator.com

website: www.wjcreator.com